Step One – Clean Tanks

The first step of the journey is our five-tank, progressive-wash, clean line system. Each part is washed and flushed in the clean line’s five tanks. Essentially, each part takes a bath. They get progressively cleaner (inside and out until they’ve satisfied customer specs.

In short, this process removes any oil, cutting fluid, mill scale, and welding scale. Additional clean measures can also be taken when needed. For example, we can shoot foam plugs, lengthen the variable flush times, and perform other cleaning functions as specified.

That said, it isn’t enough to merely clean a part. DTI also has an inspection process that ensures a part meets spec.

Step Two – Inspection

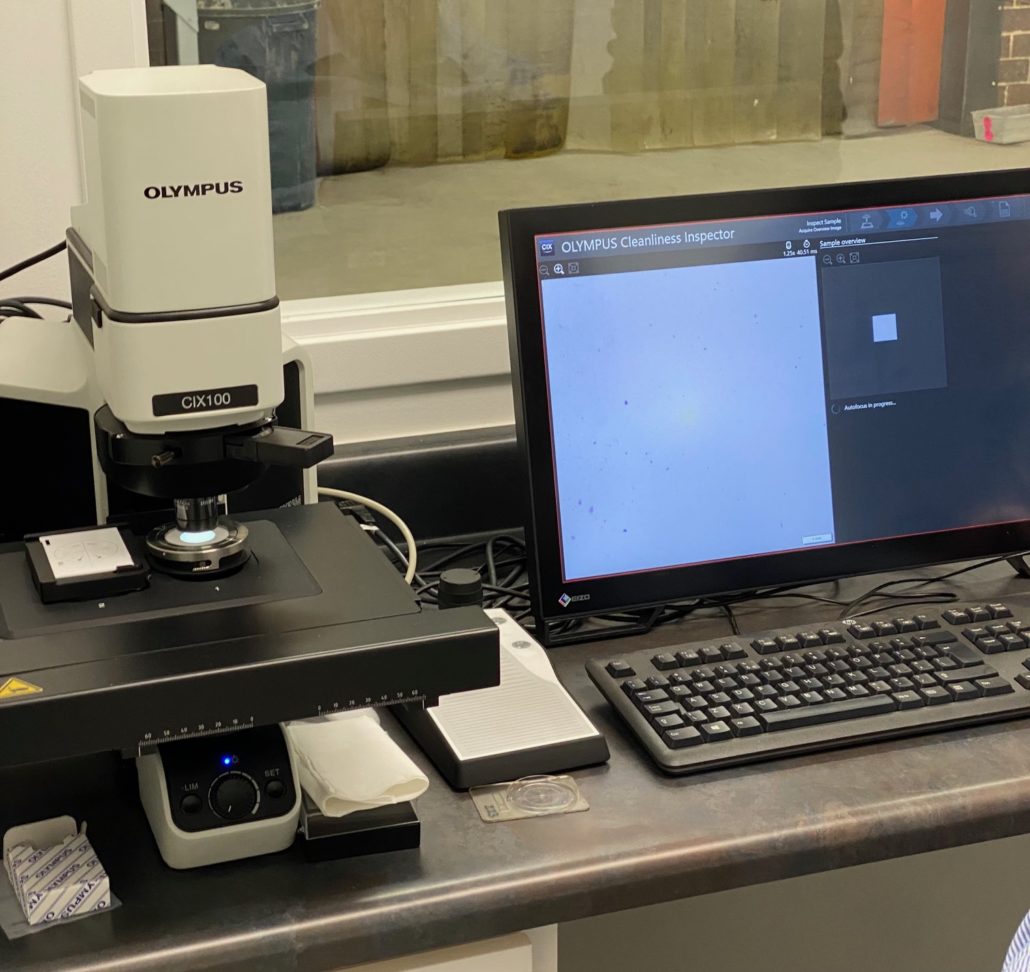

The second step is the inspection process. After the clean line, parts travel a short distance to our inspection room. The inspection room is equipped with an Olympus CIX 100 cleanliness microscope.

It features industry-leading automated particle counting and inspection software. As a result, the Olympus CIX 100 can detect and count particles as small as 2.5 microns.

With the addition of the Olympus CIX 100, DTI has the ability to inspect parts with very high accuracy. As noted, DTI internal clean standards now align with many customer’s cleanliness standards. In addition, DTI can meet the following ISO clean specifications: ISO 12345, ISO 16232, ISO 4406, and ISO 4407.

The material and geometry of a part can determine its clean process and results. That said, for welded tube assemblies, DTI can reliably archive results below 200 microns. In addition, for hydraulic tube assemblies, DTI can reach results below 100 microns.

Step Three – Cap and Seal

Lastly, all clean parts are capped and sealed. The work is performed inside our inspection room. A stand-alone air filtration system prevents dust and contaminants from being reintroduced to freshly-cleaned parts.

Once parts are capped and sealed, from there, they move out into our shipping area to be packaged. Again, we pack and ship per spec and request. Thus, parts are shipped to various customer locations throughout North America.