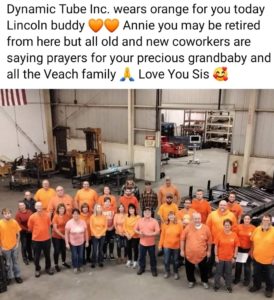

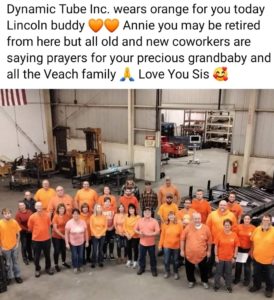

The DTI Family Supports Lincoln!

DTI wears orange to support of baby Lincoln. We are keeping Lincoln and his family in our thoughts and prayers!

DTI wears orange to support of baby Lincoln. We are keeping Lincoln and his family in our thoughts and prayers!

Dynamic Tube is hosting our next hiring event! DTI will hold a Job Fair on 8/26/21 from 3-6 PM! Come learn about our open positions at DTI and building your career path in the Manufacturing business!

#hiring #manufacturing #jobs

Looking for high-pressure diesel fuel injection lines? If so, you’ve come to the right place.

Dynamic Tube has been in continuous operation in Maquoketa, IA for over 40 years. In the beginning, DTI was purely a manufacturer of diesel lines.

Over the years, DTI has added capabilities that now include mandrel bending, pipe welding, brazing, and light assembly.

But all along, Dynamic Tube has never stopped producing high-pressure diesel fuel injection lines. All told, DTI still manufactures many thousands of diesel lines every year.

How do we do it?

In order to manage that high level throughput, DTI has established the right systems, equipment, and supply chain to make world class parts quickly, efficiently, and backed by ISO9001:2015 quality assurance.

In order to make any tubing part, the process first begins with raw tubing stock and material order management. As such, we’ve developed processes that allow us to navigate the long lead times, tariffs, and supply chain disruptions common to steel tubing.

When it comes to diesel fuel injection parts, DTI also maintains an inventory of certified carbon and stainless fuel-tubing that includes ODs of 1/4″, 5/16″, 3/8″, 4mm, 6mm, 8mm, as well as other material like 1010, ST52, and PP600.

Once a part has been quoted, and a purchase order has been received, the job can begin. At that point, the first step is to enter the XYZ bend data into our secure project Bend Pro software system.

Keep in mind, our bend machinery can perform multiple radius bends on one line (although we could have a friendly debate about whether that’s best practice from an engineering design standpoint).

We install the XYZ data of each part into our Bend Pro software, which synchronizes with our tube benders. From there, the fabrication process flies.

First, we cut the raw tubing to length. Next we deburr, chamfer, and prep the tube ends. The tubes then get sleeves. Then we end-form the tubes. End-forms can take many shapes, depending on the application. These include:

After the tube has been properly end-formed, we bend the part per print.

At this point in the process, they look like parts. However, the job isn”t done yet.

First, the shape of the part is verified to specification using one of our state of the art Romer CMM’s.

If required, DTI has an autofrettage machine that will pre-stress diesel line parts with up to 140,000 PSI. Ultimately, the pre-stress autofrettage process results in superior part strength– and fatigue resistance.

Finally, we clean all diesel lines on our automatic flush stand. Still not done. After clean, we inspect and patch-test parts to meet clean specs.

When required, at this stage we can also perform additional light-assembly. In that case, we’ll group several parts together, and install clamps or brackets to create a complete fuel assembly.

Throughout the entire fabrication process, we follow ISO9001:2015 standards to ensure the quality of our parts.

Diesel parts move from clean to our dedicated shipping area. Once in shipping, we package, label, and ship parts according to spec. When requested, we can ship using an OEM’s packaging or labels, either to a warehouse or direct to an end-user.

DTI also interfaces with logistics. We schedule freight pick-ups with carriers, deliver parts ourselves when feasible, and frequently go above and beyond to get the job done for our customers.

In summary, our diesel area is a microcosm of Dynamic Tube. Put another way, every part we manufacture at DTI follows a similar journey as our diesel lines.

That said, if you have a high-pressure diesel fuel injection lines to outsources, contact us today. If you’re a North American OEM looking for a reliable, long term supplier-partnership to bolster your supply chain– Dynamic Tube wants to work with you. Let’s talk!

Call us at 563-652-5165 to say hello, or email your prints directly to insidesales@dtitube.com.

Dynamic Tube recently approached a new customer who is dealing with a common problem.

By winning them over with our technical expertise, on-time delivery, fair pricing, and quality control, Dynamic Tube solved their problem.

The Problem

For as long as anyone remembers, they’ve been fabricating all their own bent tubing parts in-house. Now, a handful of factors have come into play that has made it wise to investigate transferring their bent tubing parts to an outside source. Technological advances have allowed them to create a better product. And this customer is on the right side of Moore’s Law, adapting and evolving in turn.

In short, our customer’s end-users declared their preference for a different, more complex end-form to their tubing. One that our customer was not properly tooled for. Moreover, their new Machine designs have doubled the number of tubes they use, increasing part volume. And with more tubes in confined space, Engineering was required to add more complexity in their bends.

They Say Busy Is Good, Right?

What to do? Their new product advancements will situate them as an industry leader on the cutting edge. But it became apparent that their old in-house hand benders could not handle the increased volume and complexity of these new parts.

So the Customer performed a cost analysis. They looked at the cost of buying the dies required to make the new end-forms. They investigated purchasing a CNC bender to handle the more complex tubing bends and part volume. Ultimately the cost of a CNC bender could not be justified unless they kept it running night and day.

The Customer said, “and we don’t want to become a tube bender.” Tube bending is not part of their business model, and certainly not their core competency. After considering a cost vs. buy analysis of their bent tubing, it was determined that outsourcing was a good option.

The Era Of Specialization

That’s where Dynamic Tube comes in. Fabricated Tubing is our core competency. We specialize in attaining economy of scale with fabricated tubing. We bend tube all day, every day and have for 4o years.

By demonstrating our technical expertise and support– along with quality parts, fair pricing, and on-time delivery to the customer during the prototype and limited production builds, we earned their trust to handle not just their production volumes, but the legacy parts that had previously been hand bent.

This customer decided it was money well-spent to let us perform our job as specialists, freeing them up to focus on their core competencies.

By winning them over with our value proposition– technical expertise, fair pricing, on-time delivery, and rigid quality control, Dynamic Tube solved this customer’s build-vs-buy riddle. We now look forward to a mutually beneficial relationship that will last with a new Customer who’s excited about what we do for them

Dynamic Tube Inc. is an ISO 9001-2015 registered company. Our quality system and procedures have also been certified by several of our customers. Our internal processes are always improving to meet the needs of international standards and our customer.

DTI Quality Policy

Dynamic Tube Inc. will strive to provide Customer Satisfaction driven by the objective of continuous improvement.

1286 East Maple Street,

Maquoketa, IA 52060